See our products

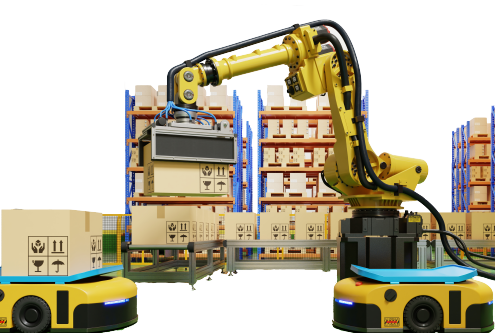

Autonomous Mobile Robot

-

LMR (Latent Mobile Robot)

-

FMR (Forklift Mobile Robot)

-

CTU (Carton Transfer Unit)

Characterized by its lifting mechanism, It has an optimized motion performance and enhanced safety protection. It helps customers create a safer working environment and more cost-effective productivity.

FMR focuses on the automatic transfer of standard bins/pallets. It adopts high precision laser SLAM navigation, vision navigation, etc.

CTU (Carton Transfer Unit) is an automated unmanned picking and handling robot. It can transfer multiple goods simultaneously which improves the picking efficiency and storage capacity.

Virtual Reality for Industrial Training

-

Equipment Operation

-

Maintenance Procedures

-

Safety Training

-

Soft Skills Training

VR can simulate the operation of complex machinery, allowing employees to practice skills before using real equipment.

VR can guide employees through step-by-step maintenance tasks, ensuring proper procedures are followed.

VR can simulate emergency scenarios, teaching employees how to respond effectively to hazards.

VR can be used to practice communication, teamwork, and leadership skills in a safe and controlled environment.

Service Robot

-

Waitress Robot

-

Concierge Robot

These robots are used in restaurants to take orders and deliver food.

Designed to assist guests in hotels, hospitals, and other hospitality settings. They can perform various tasks such as providing information, giving directions, making reservations, and even delivering items to guest rooms.

Maintenance

-

Preventive Maintenance

-

Predictive Maintenance

-

Corrective Maintenance

-

Condition-Based Maintenance

-

Reliability Maintenance

This is the most common type of maintenance, and it involves regularly scheduled inspections, cleaning, and repairs to prevent breakdowns. It can be time-based (e.g., every 6 months) or usage-based (e.g., every 10,000 cycles).

This can help to further improve maintenance efficiency and reduce costs.

This type of maintenance is performed after a failure has occurred. It is typically more expensive than preventive maintenance because it often involves replacing parts or entire systems.

CBM uses sensors and other monitoring devices to track the condition of equipment and predict when maintenance is needed. This can help to avoid unexpected breakdowns and optimize maintenance schedules.

Maintenance that considers the safety, environmental, and economic consequences of equipment failure. It aims to develop maintenance strategies that will minimize the risk of failure and maximize the life of equipment